Safety Relay: verschil tussen versies

(→Safety Relay) |

|||

| (18 tussenliggende versies door 2 gebruikers niet weergegeven) | |||

| Regel 1: | Regel 1: | ||

| − | + | [[Category:Nodes & network devices]][[Category:Safety]] | |

| + | [[Bestand:Safetyrelay.jpg|miniatuur|Veiligheidscontactor]] | ||

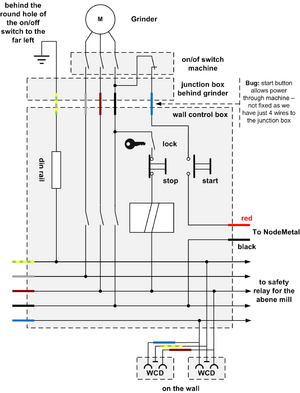

| + | [[Bestand:grinder-schematic.png|miniatuur|magnetic on-off switch used on most 400VAC machines]] | ||

| − | + | We use safety relays/magnetic on-off relays in many places; these prevent that a machine powers back on after a power loss. | |

| − | [[ | + | It also prevents powering back on after someone pressed the emergency button. |

| + | |||

| + | And it ensures the power is turned off immediately after pressing the emergency button, the stop button, an overheat/overload situation or a lock-out situation. In some cases it is also integrated in the [[https://wiki.makerspaceleiden.nl/mediawiki/index.php/Categorie:ACNode Access control system]]. | ||

| + | |||

| + | == 3 phase power machines == | ||

| + | Most are a variation of the [[Large Stationary Grinder / Slijpmachine]], [[Metal Mitresaw / Afkortzaag Metaal|Metal Mitresaw]] or the [[Circular Table Saw / Tafelcirkelzaag]] circuit. These are based on a product such as: https://www.hydrauliek24.nl/motor-beveiligingsschakelaar-7-10-a or on normal contractors with a load limiter (see yellow crate for more of these). | ||

| + | |||

| + | == Small machines == | ||

Some of the small machines use a 4 or 5 pin `on-off' button such as https://www.amazon.de/-/en/Hefddehy-Waterproof-Magnetic-Button-220-240V/dp/B0BYNGHLJ5/ref=sr_1_10 or https://www.amazon.de/-/en/KEDU-KJD17-Flush-Mounted-Switch-Voltage/dp/B07956F8TN/ref=d_pd_day0_sccl_2_1/257-4034223-4086038 | Some of the small machines use a 4 or 5 pin `on-off' button such as https://www.amazon.de/-/en/Hefddehy-Waterproof-Magnetic-Button-220-240V/dp/B0BYNGHLJ5/ref=sr_1_10 or https://www.amazon.de/-/en/KEDU-KJD17-Flush-Mounted-Switch-Voltage/dp/B07956F8TN/ref=d_pd_day0_sccl_2_1/257-4034223-4086038 | ||

| Regel 9: | Regel 18: | ||

These are wired as thus: | These are wired as thus: | ||

| − | [[Bestand:Wiring-4-5-pin.jpg| | + | [[Bestand:Wiring-4-5-pin.jpg|400px|Magnetic on-off switch]] |

| + | |||

| + | where there is often a [[https://en.wikipedia.org/wiki/Electrical_contact Normally Closed]] [[https://nl.wikipedia.org/wiki/Clixon Clixon temperate sensor]] in the motor that also switches the machine off (e.g just like the emergency stop button). | ||

| + | |||

| + | = Typical test = | ||

| + | |||

| + | # Check on/off function | ||

| + | # Verify that the overload setting is set right | ||

| + | # Turn on, drop mains power for 1 second; verify that unit does not come back on | ||

| + | # Turn on; press emergency button and verify off. | ||

| + | # Press emergency button and verify that pressing 'on' will not turn it on (no matter how shortly) | ||

| + | # Repeat above two steps for every emergency button (and temperature clickson) | ||

| + | # Repeat above two steps for the overload 'test' button | ||

| + | # Put operator switch in the 'on' position; and check that you cannot power the machine on (no matter how shortly) | ||

| + | # Verify that pressing 'off' will work even when the operator switch is on or 'on' is held | ||

| + | |||

| + | = Notice = | ||

| + | |||

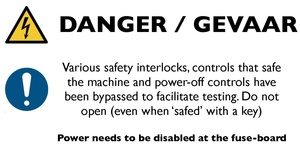

| + | [[Bestand:Unsafe-warning.pdf|miniatuur]] | ||

| + | |||

| + | Occasionally you need to bypass the relay and/or the main connection to the power safeties. Putting this note up is good practice. | ||

Versie van 2 nov 2024 om 12:53

We use safety relays/magnetic on-off relays in many places; these prevent that a machine powers back on after a power loss.

It also prevents powering back on after someone pressed the emergency button.

And it ensures the power is turned off immediately after pressing the emergency button, the stop button, an overheat/overload situation or a lock-out situation. In some cases it is also integrated in the [Access control system].

3 phase power machines

Most are a variation of the Large Stationary Grinder / Slijpmachine, Metal Mitresaw or the Circular Table Saw / Tafelcirkelzaag circuit. These are based on a product such as: https://www.hydrauliek24.nl/motor-beveiligingsschakelaar-7-10-a or on normal contractors with a load limiter (see yellow crate for more of these).

Small machines

Some of the small machines use a 4 or 5 pin `on-off' button such as https://www.amazon.de/-/en/Hefddehy-Waterproof-Magnetic-Button-220-240V/dp/B0BYNGHLJ5/ref=sr_1_10 or https://www.amazon.de/-/en/KEDU-KJD17-Flush-Mounted-Switch-Voltage/dp/B07956F8TN/ref=d_pd_day0_sccl_2_1/257-4034223-4086038

These are wired as thus:

where there is often a [Normally Closed] [Clixon temperate sensor] in the motor that also switches the machine off (e.g just like the emergency stop button).

Typical test

- Check on/off function

- Verify that the overload setting is set right

- Turn on, drop mains power for 1 second; verify that unit does not come back on

- Turn on; press emergency button and verify off.

- Press emergency button and verify that pressing 'on' will not turn it on (no matter how shortly)

- Repeat above two steps for every emergency button (and temperature clickson)

- Repeat above two steps for the overload 'test' button

- Put operator switch in the 'on' position; and check that you cannot power the machine on (no matter how shortly)

- Verify that pressing 'off' will work even when the operator switch is on or 'on' is held

Notice

Occasionally you need to bypass the relay and/or the main connection to the power safeties. Putting this note up is good practice.