Large Stationary Grinder / Slijpmachine: verschil tussen versies

(→Operating the machine) |

(→Safety) |

||

| Regel 13: | Regel 13: | ||

The main safety issues are getting grabbed by the wheel (it is a powerful 3-fase machine) and sparks/flying bits. | The main safety issues are getting grabbed by the wheel (it is a powerful 3-fase machine) and sparks/flying bits. | ||

| − | Wear protective eyewear, make sure you wear appropriate tight fitting clothes, no rings, jewellery and keep things like long hair well out of harms way. Be also careful with synthetic clothing - use of cotton/fire-safe fabrics is strongly advised. | + | Wear protective eyewear, make sure you wear appropriate tight fitting clothes, no rings, jewellery and keep things like long hair well out of harms way. Be also careful with synthetic clothing or anything that can burn (or melt into your skin) -- the use of cotton/fire-safe fabrics is strongly advised. There is a gray cotton coat in the workshop (near the CV). |

Be also very careful with gloves; either ensure they are very very strong (such a as the tick leather gloves used for welding) or so weak that they will tear well before your fingers or hand is pulled into the grindstone. | Be also very careful with gloves; either ensure they are very very strong (such a as the tick leather gloves used for welding) or so weak that they will tear well before your fingers or hand is pulled into the grindstone. | ||

| Regel 19: | Regel 19: | ||

It is OK to operate the machine alone. | It is OK to operate the machine alone. | ||

| − | With respect to noise - be kind and considerate after 19:00 - and limit yourself to sporadic low-noise use. | + | With respect to noise - be kind and considerate after 19:00 - and limit yourself to sporadic low-noise use. Use ear-protection when appropriate. |

| + | |||

| + | Other points of note: | ||

| + | |||

| + | # Check the wheel for cracks - if any appear - stop using it. | ||

| + | # Make sure the rests are close to the wheels (about 2-3mm). | ||

| + | # Do not adjust the rests while the machine is spinning. | ||

| + | # Use a dusk mask/protection when appropriate. | ||

== Operating the machine == | == Operating the machine == | ||

Versie van 15 jan 2018 om 10:25

Inhoud

Grote Staande Slijpert

The large grinder is located in the metal workshop. It is often used to sharpen tools; including those from the wood workshop.

Safety

The machine requires mandatory instructions, [liability waiver] on file and approval from the trustees.

The main safety issues are getting grabbed by the wheel (it is a powerful 3-fase machine) and sparks/flying bits.

Wear protective eyewear, make sure you wear appropriate tight fitting clothes, no rings, jewellery and keep things like long hair well out of harms way. Be also careful with synthetic clothing or anything that can burn (or melt into your skin) -- the use of cotton/fire-safe fabrics is strongly advised. There is a gray cotton coat in the workshop (near the CV).

Be also very careful with gloves; either ensure they are very very strong (such a as the tick leather gloves used for welding) or so weak that they will tear well before your fingers or hand is pulled into the grindstone.

It is OK to operate the machine alone.

With respect to noise - be kind and considerate after 19:00 - and limit yourself to sporadic low-noise use. Use ear-protection when appropriate.

Other points of note:

- Check the wheel for cracks - if any appear - stop using it.

- Make sure the rests are close to the wheels (about 2-3mm).

- Do not adjust the rests while the machine is spinning.

- Use a dusk mask/protection when appropriate.

Operating the machine

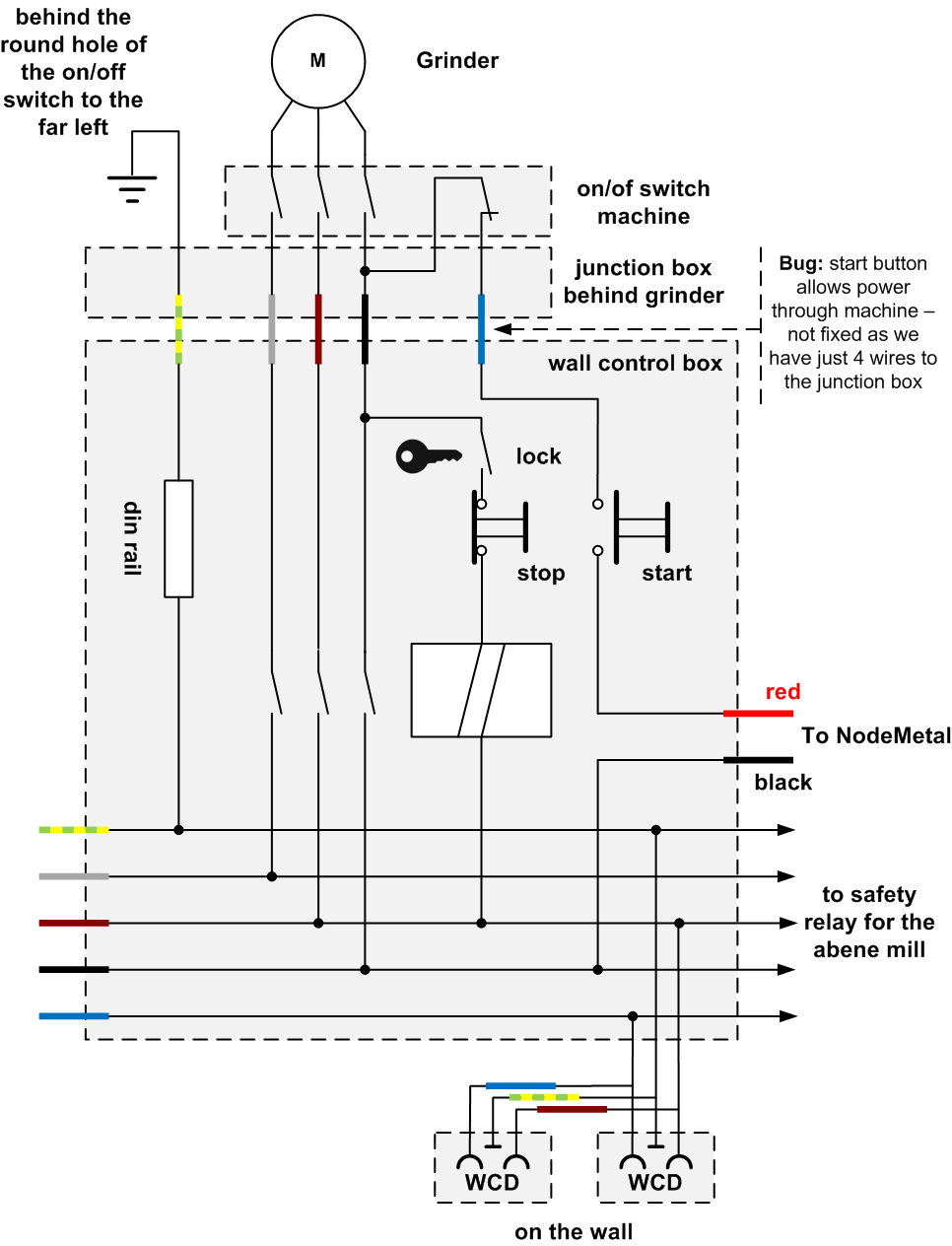

The machine has a safety relay. This stops the machines from starting unattended.

To power on the machine:

- Ensure that the round on-off switch on machine (middle of the pedestal) is in the off position.

- Press the green 'on' button on the wall control box (to the right of the grinder; just past the desk with the drill press)

- Use the round on-off switch on machine (middle of the pedestal) during use.

To power off the machine:

- Ensure that the round on-off switch on machine (middle of the pedestal) is in the off position.

- Press the red 'off' button on the wall control box (to the right of the grinder; just past the desk with the drill press)

To put the machine into `out of order' mode.

- Ensure that the round on-off switch on machine (middle of the pedestal) is in the off position.

- Press the red 'off' button on the wall control box (to the right of the grinder; just past the desk with the drill press)

- Take the key which is inside the control box and use that to operate the keylock of the grinder; setting it it '0'.

- If you are very concerned about someone re-enabling it - then hand the key to one of the trustees or put it in the mailbox of a trusteed (the one where you sent the [liability waiver] to).

- Report the issue to the mailing list.

Aluminium

There are currently no rules around what materials can be ground.

Ritsen / Dressing of the wheel

There is a diamond dresser / diamand-ritser for the grinder - this allows us to keep the surface nice and smooth. Alex has made a nice holder for it which makes use relatively easy.

Ask on the mailing list for someone to show you how that is done.

Safety Relay wiring

The safety relay is currently a standard safety relay setup with a small twist; rather than use the spare NO (or an NC) on the relay - we abuse the 'free' blue wire in the existing cable in conjunction with the NC of the grinder switch. This lets us prevent powering up the relay when the on/off switch is in the wrong position. But it does mean that we allow power to one of the phases of the grinder while pressing the button. That is not ideal.

Other issues of note:

- the grounding is through the DIN rail.

- There are some junctions in N and L1 hiding in the bottom part of the unit.

- Some of the one step short jumpers are recycled multi-steps; so there is some exposed copper where there should not be any.

- We've had issues with the reliability of the NC push buttons.