VK2000-build: verschil tussen versies

(→Wiring) |

(→Heatsensor - Wiring) |

||

| Regel 48: | Regel 48: | ||

[[Bestand:scan-FITH-NP5R.pdf|60px|Scan Manual Sokkel]] | [[Bestand:scan-FITH-NP5R.pdf|60px|Scan Manual Sokkel]] | ||

| − | == | + | == Heat Alarm - Wiring == |

* Mains - 'tick' cable going to distribution panel | * Mains - 'tick' cable going to distribution panel | ||

Versie van 31 jan 2024 om 17:36

Inhoud

Wiring

- N and single 220volt L via switch; black and blue

- 2x for the thermocouple - orange cable; white and brown

- 2x Normally open relays to switch a load contactor

- Earth wire

On a Harting HAN7Da connector.

RCD / Aardlekschakelaar

40A, 500mA residual current detector/aartlekschakelaar in de loop. It sits in the path to the 4+1 IEC wall socket.

kWh meter

Dit is een DTS353 -- https://www.rdlmeters.com/product/dts353/ met een Watt-uur puls uitgang.

Deze is vermoedelijk low-voltage open collector. Plan is te beginnen met 3v3 volt en een 4.7 kΩ pull up resistor on the IO port of the node..

Sensor

- Nenniger GmbH, Berlin, Hochtemperatur S-Type Thermocouple

- Special type of cable for this (orange)

Hitte Sensor

een FIT-NP5R dry-relay (NO, NC) sokkel met een FITH-23010 hitte sensor.

Manuals as shipped

Actual manuals that were shipped with the unit (please keep)

Heat Alarm - Wiring

- Mains - 'tick' cable going to distribution panel

- L -- Phase 220v, Brown

- N -- Neutral, 220v, Blue

- Earth - terminated, Yellow

- Alert-signal, white -- not connected

- Dry relay - galvanically separate from mains - 'thin' cable going to oven control box

- Black - common

- Red - Normally open

- Blue - Normally closed

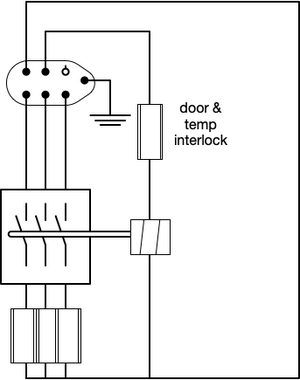

VK2000 Control signals

Our version has 2 relays; with an NO to the 'L'.

- Earth wire (yellow/green)

- Neutral wire (for the AC/DC) (blue)

- L wire (for AC/DC and as the feed of the relay outputs) (brown)

- Relay 1 out -- switching to L (black)

- Relay 2 out -- Switching to L (green)

- Purple wire - not connected

- Orange wire - white/brown - Pt

Manual

Wiring Oven side =

Harting style 6+1 connector carrying 3 phase power and relay control signal

- 2 pins for Neutral and Switch (relay)

- 3 pins for the 3 phases

- E pin for Earth

todo

Probably needs a snubber

Risks

Inherent

- Heat runaway (CPU fault, contacts welded)

- Faulty thermocouple causing heat runaway / instability / cracking

- Contact with water/leak

- Material falling onto it / other people working too near / unclear that is hot

- Touching hot material in oven / once out of oven

Operator driven

- Flammable material near

- Hot handles, etc

- Dust

- Unclear it is on / hot

- Opening while hot

- Bare wire touching

- Looking into it / infrared radiation

- Toppling, bumping, people/things pushed into it

- Welding equipment nearby that may be flammable

- Use of the corner by a third party for flammable things (e.g. spray painting)

Measures

- Touching bare metal electric coils / electrocution risk

- Instructions

- Interlock on door/lid (touching bare metal electric coils)

- Earth leak trip/detector (touching bare metal electric coils)

- Runaway heat

- VK2000 validates heat/cool & stops firing outside control range

- Heat sensor above oven

- Heat fuse 1 (firing relay), heat fuse 2 (interlock)

- Overcurrent protection

- Check ACNode for current & firing

- Emergency button

- No unknown/uncontrolled states on powerup / after powerlock

- Signage (eye, heat, ..)

- Safe location, 2 sides wall

- Personal Safety Equipment (gloves, safety gogles, welding mask/googles)

- Instructions