VK2000-build: verschil tussen versies

(→kWh meter) |

(→Wiring kWh meter too ACNode) |

||

| Regel 32: | Regel 32: | ||

Zwarte audio kabel die rechts boven de kast in komt. | Zwarte audio kabel die rechts boven de kast in komt. | ||

| − | [[Bestand:Dts353-oc-output|120px]] | + | [[Bestand:Dts353-oc-output.png|120px]] |

* Schroef terminal 8; Plus; center van coax (rode terminal), dan naar rood van het plugje aan de kant van het PCB | * Schroef terminal 8; Plus; center van coax (rode terminal), dan naar rood van het plugje aan de kant van het PCB | ||

Versie van 7 feb 2024 om 20:58

Inhoud

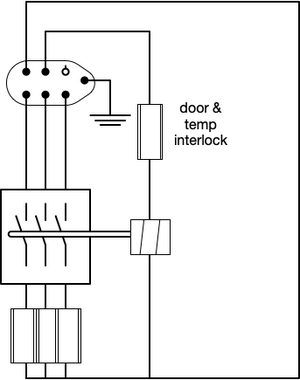

Wiring

- N and single 220volt L via switch; black and blue

- 2x for the thermocouple - orange cable; white and brown

- 2x Normally open relays to switch a load contactor

- Earth wire

On a Harting HAN7Da connector.

RCD / Aardlekschakelaar

40A, 500mA residual current detector/aartlekschakelaar in de loop. It sits in the path to the 4+1 IEC wall socket.

kWh meter

Dit is een DTS353 -- https://www.rdlmeters.com/product/dts353/ met een Watt-uur puls uitgang.

Deze is vermoedelijk low-voltage open collector. Plan is te beginnen met 3v3 volt en een 4.7 kΩ pull up resistor on the IO port of the node..

Wiring kWh meter too ACNode

Zwarte audio kabel die rechts boven de kast in komt.

- Schroef terminal 8; Plus; center van coax (rode terminal), dan naar rood van het plugje aan de kant van het PCB

- Schroef terminal 9; Minus; aarde van de coax (zwarte terminal), dan naar bruin van het plugje aan de kant van het PCB

Sensor

- Nenniger GmbH, Berlin, Hochtemperatur S-Type Thermocouple

- Special type of cable for this (orange)

Heat Alarm

een FIT-NP5R dry-relay (NO, NC) sokkel met een FITH-23010 hitte sensor.

Heat Alarm Manuals as shipped

Actual manuals that were shipped with the unit (please keep)

Heat Alarm - Wiring

- Mains - 'tick' cable going to distribution panel

- L -- Phase 220v, Brown

- N -- Neutral, 220v, Blue

- Earth - terminated, Yellow

- Alert-signal, white -- not connected

- Dry relay - galvanically separate from mains - 'thin' cable going to oven control box

- Black - common

- Red - Normally open

- Blue - Normally closed

VK2000 Control signals

Our version has 2 relays; with an NO to the 'L'.

- Earth wire (yellow/green)

- Wired to a distribution bar on the back panel

- Neutral wire (for the AC/DC) (blue)

- Wired post the main switch

- L wire (for AC/DC and as the feed of the relay outputs) (brown)

- Wired post the main switch, current limiter and SafetyRelay

- Relay 1 out -- switching to L (black)

- Wired to the main control relay via the red cable *inside* the oven

- Relay 2 out -- Switching to L (green)

- Wired to Opto1 of the NodeCeramic

- Purple wire - not connected

- Orange wire - white/brown - Pt

- wired to the Pt sensor inside the Oven

Manual

Wiring Oven side =

Harting style 6+1 connector carrying 3 phase power and relay control signal

- 2 pins for Neutral and Switch (relay)

- 3 pins for the 3 phases

- E pin for Earth

todo

Probably needs a snubber

Risks

Inherent

- Heat runaway (CPU fault, contacts welded)

- Faulty thermocouple causing heat runaway / instability / cracking

- Contact with water/leak

- Material falling onto it / other people working too near / unclear that is hot

- Touching hot material in oven / once out of oven

Operator driven

- Flammable material near

- Hot handles, etc

- Dust

- Unclear it is on / hot

- Opening while hot

- Bare wire touching

- Looking into it / infrared radiation

- Toppling, bumping, people/things pushed into it

- Welding equipment nearby that may be flammable

- Use of the corner by a third party for flammable things (e.g. spray painting)

Measures and Controls

- Touching bare metal electric coils / electrocution risk

- Instructions

- Interlock on door/lid (touching bare metal electric coils)

- Earth leak trip/detector (touching bare metal electric coils)

- Runaway heat

- VK2000 validates heat/cool & stops firing outside control range

- Heat sensor above oven

- Heat fuse 1 (firing relay), heat fuse 2 (interlock)

- Overcurrent protection

- Check ACNode for current & firing

- Emergency button

- Present and relatively far from oven / some shielding by beam

- No unknown/uncontrolled states on powerup / after powerlock

- Signage (eye, heat, ..)

- Copy part of the documentation

- Safe location, 2 sides wall

- Removal overly hard - presence of beam, welding table, controls screwed to the wall & limited cable length. Spacers behind/between legs and wall

- Personal Safety Equipment (gloves, safety gogles, welding mask/googles)

- Part of the instructions

- 'on loan' material always available & nearby

- Mandatory Instructions

- Tag system

- Instructions can only be entered by those who had instruction or with trustee override