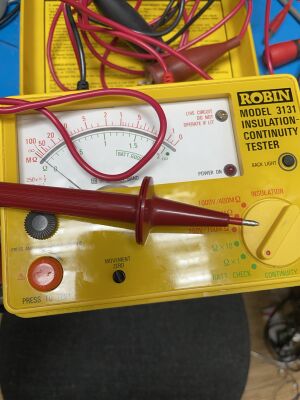

Megger / Insulation Meter

A "Megger" or Insulation meter [wikipedia] - can be used to measure the isolation; for example of our 3 phase motors in the Metal Mitresaw, the Circular Table Saw or any of our normal 2 phase electric machines. It helps ascertain that the device is safe to use.

It works by putting 500V or a 1000V across the measuring probes and then checking, measuring, if the resistance is well in the high mega ohms.

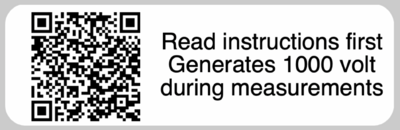

This means that, during measurement, there is a lethal, 1000V, across the probes !

So you must use well isolated test probes - and not hold these in your hand.

Measuring Isolation/Leakage

- Set the meter to the battery test.

- Press the orange button and make sure it is in the `good' range.

- Set the meter to 500V or 1000V.

- Press the orange button shortly while nothing is connected.

- Check that the dial `just' moves. If not - use the back zero adjust so that it just moves if you press the orange button.

- Check that the red 'ON' LED is off. If not - turn the orange dial to make it release.

- Visually check the probes - there should be no cracks or bare metal visible except at the very ends

- Connect the probes to the device.

- On the machine you want to test - make sure it is as switched 'on' as is feasible (as otherwise we just test the isolation of the power cable). E.g. on a corded drill with grounding - switch & lock it in the 'on setting'. Know that on some of our 3 phase machines - the build in safeties prevent exactly this. On those machines the testing process requires a second set of test where you connect on the motor directly or after the safety relay (and usually requires removing the star/delta bridge).

- Connect one probe to earth and the other to one of the pins of the plug.

- Make sure your hands are no-where near the probes - as in the next step you will energise them to a thousand volts.

- Step back. Press the orange button. Be careful, There is now a 1000V across the probes

- Read out the resistance; it should be in the high mega ohms (note the red scale multiplier):

- So if you have it set to 1000V; and it reads '5' you have to multiply the value by 2.

- So if you have it set to 250V; and it reads '5' you have to divide the value by 2.

- Let go of the orange button

- Now test Earth versus the other pin.

- Where relevant; e.g. when the metal housing is not grounded; also measure between the housing an the pins

Typical use

It is common in workshops to test all electrical equipment once a year.

For this the machine MUST be disconnected from the mains -or- the fuses in the fusebox need to be removed.

For most of our three phase motors this usually means disconnecting the Star/Delta cross connects on the motor & doing each 3 versus each other and versus the grounding. And then rewiring it again.

Usually a good idea to take a photo of the wiring before you disconnect.

So in that case you'd remove the wires from both sides of all 3 coils. That leaves you with 6 contacts. Often called something like A1, A2, B1/2, C1/2 or P1/2, Q1/2, R1/2 or similar (or U,V,W).

You then check that A1/A2 are having a very low conductivity with the continuity check. And same for B1/2 and C1/C2. It is also good to check motor earth/casing and earth. And earth near the motor and earth in the plug.

Next you check that you measure `no continuity' i.e. high resistance value (i.e. no short) between A and B, B and C and C and A. As well as between A and earth, B and earth, and C and earth.

You then put the meter in isolation mode and repeat the previous checks; but now for more `real'.

I.e. wire one wire up to A and the other to B. And check you get that you STILL get a high number of megaohms; Same for B to C and C to A. And between A and earth, B and earth and finally C and earth. Values should be well above 2 Mohm and similar if the motor is dry and has ran in the last weeks.

Set

- Pouch with three test wires

- 1 black wire with a black crocodile clip

- 1 red wire with a red crocodile clip

- 1 red wire with a stift.

- Robin 3131 Unit itself

- Leather strap for carying

- Paper Manual

Safety

The unit has an extra sticker:

Documentation

Full manual

Service and Calibration manual

History

Bought by the space early 2024

Voltages and resistance up to 10Mohm last checked 1/1/2024

This equipment is safety category 4:

- In-person, instructions strongly advised but not mandatory.

- Reading, and following, the instructions on the Wiki is mandatory!

This equipment is Noise Category 3: Can be used at all hours. No limits.

Handle with care.

Handle with care.

This is a precision tool with exact dimensions and straightness.

That means: handle it gently, don't hammer on it or use it as a crowbar and so on.

(if you need a crowbar - these are wonderful for that!)

It is very important that if you accidentally drop it or think it may be out of line

- either mark the tool very clearly...

- or report this to the mailing list...

...so that your fellow makers do not ruin their work.