Surface Grinder / Vlakslijpmachine: verschil tussen versies

| (30 tussenliggende versies door 2 gebruikers niet weergegeven) | |||

| Regel 1: | Regel 1: | ||

| − | [[Category: | + | [[Category:Tools]][[Category:Metal working tools]][[Category:Metal lathe and mill tools]][[Category:SafetySheet]] |

| − | [[Category:Metal]] | + | [[Bestand:Jung-f40-asis.jpg|miniatuur|De machine]] |

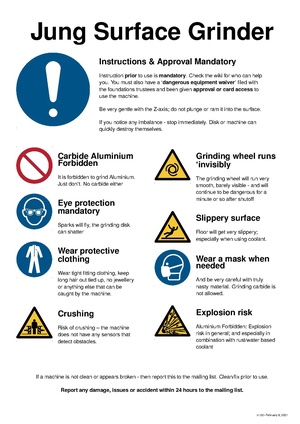

| − | [[Category:SafetySheet]] | + | [[Bestand:Jung-ssheet.pdf|miniatuur |Safetysheet Jung Surfacegrinder / Vlakslijpmachine]] |

| − | |||

| − | [[Bestand:Jung-f40.jpg|miniatuur|De machine]] | ||

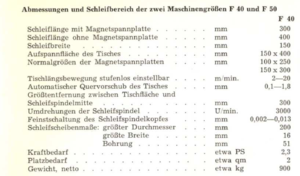

[[Bestand:Jung-specs.png|miniatuur|Specs]] | [[Bestand:Jung-specs.png|miniatuur|Specs]] | ||

| − | A late '50s, early 60's era surface grinder made by Jung. | + | A late '50s, early 60's era surface grinder made by Jung. For maintenance - see [[Surface Grinder / Vlakslijpmachine - onderhoud/maintenance informatie|this page]]. |

| − | |||

| − | For maintenance - see [[ | ||

{{SafetyCat2}} | {{SafetyCat2}} | ||

{{NoiseCat2}} | {{NoiseCat2}} | ||

| + | |||

'''Belangrijk bij gebruik: | '''Belangrijk bij gebruik: | ||

| Regel 21: | Regel 18: | ||

# Niet helemaal zeker of de leibaanoliepomp werkt. | # Niet helemaal zeker of de leibaanoliepomp werkt. | ||

| − | |||

| − | |||

| − | |||

=== Instructions - normal use === | === Instructions - normal use === | ||

| Regel 31: | Regel 25: | ||

* Make sure you have ample clearance | * Make sure you have ample clearance | ||

* Moving X direction: | * Moving X direction: | ||

| − | ** Flick the Y stop/end | + | ** Flick the Y stop/end handle to release/disconnect the hydraulic pressure |

| − | ** Push the | + | ** Push the lever on the leftmost, X-wheel outward; and push the whole wheel X forward, towards the machine, to engage. |

| − | ** You can now move the table in the X direction | + | ** You can now move the table in the X direction by spinning the wheel. If this seems hard - check that you've flicked the Y stop/end handle (fair right). |

* Moving Y direction | * Moving Y direction | ||

** Ensure that the small lever behind the Y wheel is in the middle setting. | ** Ensure that the small lever behind the Y wheel is in the middle setting. | ||

| Regel 39: | Regel 33: | ||

** You can now use the wheel to move the table in the Y direction. If it is very stiff - check if the Y-fine adjustment dial works. If so - the small knob on top of the Y wheel is in the wrong position. | ** You can now use the wheel to move the table in the Y direction. If it is very stiff - check if the Y-fine adjustment dial works. If so - the small knob on top of the Y wheel is in the wrong position. | ||

* Moving Z direction | * Moving Z direction | ||

| − | ** Rotate counterclockwise to lower, clockwise to raise | + | ** Rotate counterclockwise to lower, clockwise to raise. |

Automatic movement. | Automatic movement. | ||

* Make sure you have ample clearance | * Make sure you have ample clearance | ||

| − | * Put the speed handle all the way down | + | * Put the speed handle all the way down. |

| − | * Flick the Y | + | * Set the end stops in the right places (push button on top down to slide them left/right). |

| − | * Engage the hydraulics (requires the magchuck to be on). | + | * Flick the Y stop/end handle to release/disconnect the hydraulic pressure |

| − | * Press the round button to activate the valves. | + | * Switch the magchuck on (in the electric panel). |

| − | * Use the speed handle and rotate it gently up | + | * Engage the hydraulics on the electric panel (requires the magchuck to be on). |

| + | * Press the round leather button right of the Y wheel to activate the valves. | ||

| + | * Use the speed handle and rotate it gently up. | ||

| − | Stop | + | Stop by flicking the Y direction handle. |

The X range is set by pressing the buttons on top of the sliders down - and moving them. | The X range is set by pressing the buttons on top of the sliders down - and moving them. | ||

| − | The Y | + | The Y step is set behind the round door - by rotating the knob inside. |

| − | The Y range is set with the stoppers at the right side of the machine; below the table. These trigger the Y | + | The Y range is set with the stoppers at the right side of the machine; below the table. These trigger the Y stop/end handle handle. |

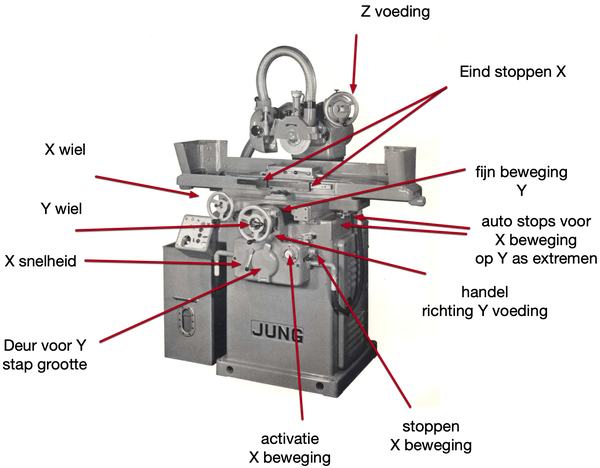

| − | + | [[Bestand:Jung-controls.png|600px|Main Controls]] | |

| − | + | === Gebruik koeling === | |

| + | Always wait with engaging the coolant until the wheel is spinning. And stop it at the same time (or before stopping) the wheel. The reason for this is balance - if it is allowed to flow while the wheel is not spinning - the wheel wil get heavier on one side; and get out of balance. | ||

| + | === Interlocks === | ||

| − | + | De hydrauliek kan niet aan als de magneet niet aan staat. Ook al is de magneet niet in gebruik. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Spindle en Slijpsteen == | == Spindle en Slijpsteen == | ||

| Regel 91: | Regel 71: | ||

* Maximale breedte: 16mm volgens folder (maar huidige is 20mm) | * Maximale breedte: 16mm volgens folder (maar huidige is 20mm) | ||

| − | |||

| − | + | == Safety / Risico's == | |

| − | |||

| − | |||

| − | + | * Risico krachten/barsten wiel | |

| − | + | * Risico kickback, bestaan safe-side | |

| − | + | * Carbite/mask/etc risks. | |

| − | |||

| − | + | * [http://web.mit.edu/course/other/machineshop/Grinder/aluminum.html Risico] [https://www.bladesmithsforum.com/index.php?/topic/8855-aluminumsteel-grindings-how-dangerous/#comment-79920_wrap van aluminium] en andere no-go/specials materials (te zacht staal) | |

| − | + | * Document dressing en aan de opgaande kant houden van de dresser onder hoek weg van 90 graden. | |

| − | + | * Document impact koeling & wiel opstart / koeling uit voordat je het wiel stopt. | |

| − | |||

| − | |||

| − | + | * Risico unbalance/uneven dressing/unbalanced mounting | |

| − | + | * Need for the covers to be on | |

| − | * | + | * Safe operator position & sufficient room, Risk of pinching, etc. |

| − | * | + | * Slippery objects/floor due to coolant spill |

| − | * | + | * Debris/dust/etc |

| − | + | == Waarschuwingen == | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

* Gevaar voor wegvliegende delen | * Gevaar voor wegvliegende delen | ||

* Gevaar voor draaiende delen | * Gevaar voor draaiende delen | ||

| Regel 134: | Regel 103: | ||

* Gevaar carbide | * Gevaar carbide | ||

* Pull-in (omgekeerde kickback - werkstuk klem tussen tafel en wiel als je het rechts van het midden zet). | * Pull-in (omgekeerde kickback - werkstuk klem tussen tafel en wiel als je het rechts van het midden zet). | ||

| + | |||

| + | == Don'ts === | ||

| + | |||

| + | * Do not strike the wheel against the material as this action could cause faults in the wheel. | ||

| + | |||

| + | * Do not clean the magnetic chuck or mount or remove work until the wheel has completely stopped. | ||

| + | * Do not start the machine until the wheel guard is in place. | ||

| + | |||

| + | * Do not stand left or right from grinding wheel when starting a grinder (or have hands there). Stand in the operator position. | ||

| + | |||

| + | * Do not apply work too quickly to a cold wheel or disk. | ||

| + | |||

| + | * Do not jam work into the wheel. | ||

| + | |||

| + | * Never reach above or around a moving wheel. | ||

== Voorzieningen == | == Voorzieningen == | ||

| + | |||

* Veiligheidsbril | * Veiligheidsbril | ||

* Veilige kleiding | * Veilige kleiding | ||

| Regel 141: | Regel 126: | ||

* Kappen | * Kappen | ||

* Noodstop | * Noodstop | ||

| + | * Juiste positie | ||

== Maatregelen == | == Maatregelen == | ||

| − | * Locatie noodstop onderdeel instructie | + | |

| + | * Locatie noodstop als onderdeel instructie | ||

* Veiligheidsbril | * Veiligheidsbril | ||

* Veilige kleiding, haarnet | * Veilige kleiding, haarnet | ||

| Regel 151: | Regel 138: | ||

* Stappenplan voor in gebruik nemen nieuwe slijpsteen | * Stappenplan voor in gebruik nemen nieuwe slijpsteen | ||

* Instructies/uitleg wat de doen bij beschadigd wiel. | * Instructies/uitleg wat de doen bij beschadigd wiel. | ||

| + | * Benadruk in koeling instructie waarom water onbalans kan geven. | ||

| + | * Benadruk in instructie dat goed plat & groot genoeg essentieel zijn voor de magchuck - en laat zien hoe je met 'dingen er omheen' kan werken. | ||

| − | + | Zie ook https://www.hse.gov.uk/pubns/priced/hsg17.pdf | |

| − | |||

| − | Zie | ||

=== Koeling, Filter en pomp === | === Koeling, Filter en pomp === | ||

| − | + | Prior to use - check that the filter is clean/empty. Empty it after use (bag can simply be emptied into the bin). | |

| − | |||

== Locatie == | == Locatie == | ||

| Regel 169: | Regel 155: | ||

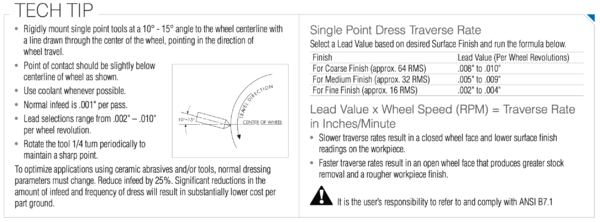

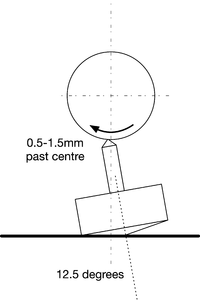

[[Bestand:Jung-angle-dressing.png|600px|Slight offset for dressing with single point]] | [[Bestand:Jung-angle-dressing.png|600px|Slight offset for dressing with single point]] | ||

| − | + | See [[Bestand:Norton-sales.pdf|20px|this norton guide]] for more information. | |

| − | + | [[Bestand:Jung-angle-dressing-thing.jpg|200px|Experimental dresser thingy]] | |

| + | [[Bestand:Jung-angle-dressing-thing-2.jpg|200px|Experimental dresser thingy]] | ||

| + | [[Bestand:Jung-angle-dressing-thing-3.png|200px|Experimental dresser thingy]] | ||

| − | + | Can be placed in 4 positions and will easily click of the magchuck if things go wrong. | |

| + | See also the info on [[Diamond dresser / Ritser]]. | ||

| − | + | == History == | |

| − | |||

| − | + | {| class="wikitable" | |

| + | |- | ||

| + | ! Datum !! Wie !! Wat | ||

| + | |- | ||

| + | | 2020-12 || dirkx || Nieuwe druklagers hydrauliek | ||

| + | |- | ||

| + | | 2021-1|| dirkx || Leibaanolie ververst | ||

| + | |- | ||

| + | | 2021-1-20 || dirkx || Koelmiddel ververst. | ||

| + | |- | ||

| + | | 2021-1-5 || dirkx || 2x nieuwe diamand ritsers | ||

| + | |- | ||

| + | | 2021-2-1 || dirkx || Nieuwe pomp, nieuwe slangen, nieuwe schakelaars | ||

| + | |- | ||

| + | |} | ||

Huidige versie van 16 nov 2024 om 23:44

A late '50s, early 60's era surface grinder made by Jung. For maintenance - see this page.

This equipment is safety category 2:

- Mandatory instructions.

- [liability waiver] on file.

- Approval from trustees, but ok to operate alone

- (but be careful/ensure you have assistance when handling very large things).

This equipment is Noise Category 2:

Can be used at all hours, but in moderation.

Be considerate; if you feel you need to wear ear protection,

then only use the tool between 07:00 and 19:00.

Belangrijk bij gebruik:

- Autofeed naar voren werkt niet goed.

- Handeltje loshalen X as is lam (moet nieuw veertje in).

- Niet helemaal zeker of het spindel goed doorgesmeerd is

- Niet helemaal zeker of de leibaanoliepomp werkt.

Inhoud

Instructions - normal use

Manual movement

- Make sure you have ample clearance

- Moving X direction:

- Flick the Y stop/end handle to release/disconnect the hydraulic pressure

- Push the lever on the leftmost, X-wheel outward; and push the whole wheel X forward, towards the machine, to engage.

- You can now move the table in the X direction by spinning the wheel. If this seems hard - check that you've flicked the Y stop/end handle (fair right).

- Moving Y direction

- Ensure that the small lever behind the Y wheel is in the middle setting.

- Make sure that the small knob on top of the Y wheel is in the loose connection.

- You can now use the wheel to move the table in the Y direction. If it is very stiff - check if the Y-fine adjustment dial works. If so - the small knob on top of the Y wheel is in the wrong position.

- Moving Z direction

- Rotate counterclockwise to lower, clockwise to raise.

Automatic movement.

- Make sure you have ample clearance

- Put the speed handle all the way down.

- Set the end stops in the right places (push button on top down to slide them left/right).

- Flick the Y stop/end handle to release/disconnect the hydraulic pressure

- Switch the magchuck on (in the electric panel).

- Engage the hydraulics on the electric panel (requires the magchuck to be on).

- Press the round leather button right of the Y wheel to activate the valves.

- Use the speed handle and rotate it gently up.

Stop by flicking the Y direction handle.

The X range is set by pressing the buttons on top of the sliders down - and moving them.

The Y step is set behind the round door - by rotating the knob inside.

The Y range is set with the stoppers at the right side of the machine; below the table. These trigger the Y stop/end handle handle.

Gebruik koeling

Always wait with engaging the coolant until the wheel is spinning. And stop it at the same time (or before stopping) the wheel. The reason for this is balance - if it is allowed to flow while the wheel is not spinning - the wheel wil get heavier on one side; and get out of balance.

Interlocks

De hydrauliek kan niet aan als de magneet niet aan staat. Ook al is de magneet niet in gebruik.

Spindle en Slijpsteen

Slijpsteen:

- Gat: 51mm

- Maximale diameter: 200mm (bij 3000rpm -> 200x3.16/3000/60=35meter/seconde)

- Maximale breedte: 16mm volgens folder (maar huidige is 20mm)

Safety / Risico's

- Risico krachten/barsten wiel

- Risico kickback, bestaan safe-side

- Carbite/mask/etc risks.

- Risico van aluminium en andere no-go/specials materials (te zacht staal)

- Document dressing en aan de opgaande kant houden van de dresser onder hoek weg van 90 graden.

- Document impact koeling & wiel opstart / koeling uit voordat je het wiel stopt.

- Risico unbalance/uneven dressing/unbalanced mounting

- Need for the covers to be on

- Safe operator position & sufficient room, Risk of pinching, etc.

- Slippery objects/floor due to coolant spill

- Debris/dust/etc

Waarschuwingen

- Gevaar voor wegvliegende delen

- Gevaar voor draaiende delen

- Gevaar voor letsel aan de handen

- Gevaar carbide

- Pull-in (omgekeerde kickback - werkstuk klem tussen tafel en wiel als je het rechts van het midden zet).

Don'ts =

- Do not strike the wheel against the material as this action could cause faults in the wheel.

- Do not clean the magnetic chuck or mount or remove work until the wheel has completely stopped.

- Do not start the machine until the wheel guard is in place.

- Do not stand left or right from grinding wheel when starting a grinder (or have hands there). Stand in the operator position.

- Do not apply work too quickly to a cold wheel or disk.

- Do not jam work into the wheel.

- Never reach above or around a moving wheel.

Voorzieningen

- Veiligheidsbril

- Veilige kleiding

- Spoeling

- Kappen

- Noodstop

- Juiste positie

Maatregelen

- Locatie noodstop als onderdeel instructie

- Veiligheidsbril

- Veilige kleiding, haarnet

- Gebruik stofmaster en spoeling bij carbinde, onderdeel instructie

- Werken aan/vanaf de 'opgaande' kant - zodat het voorwerp zich niet tussen tafel en wiel kan trekken

- Instructie wachten op stoppen wiel

- Stappenplan voor in gebruik nemen nieuwe slijpsteen

- Instructies/uitleg wat de doen bij beschadigd wiel.

- Benadruk in koeling instructie waarom water onbalans kan geven.

- Benadruk in instructie dat goed plat & groot genoeg essentieel zijn voor de magchuck - en laat zien hoe je met 'dingen er omheen' kan werken.

Zie ook https://www.hse.gov.uk/pubns/priced/hsg17.pdf

Koeling, Filter en pomp

Prior to use - check that the filter is clean/empty. Empty it after use (bag can simply be emptied into the bin).

Locatie

In de Metaalwerkplaats.

Angle for dressing

Can be placed in 4 positions and will easily click of the magchuck if things go wrong. See also the info on Diamond dresser / Ritser.

History

| Datum | Wie | Wat |

|---|---|---|

| 2020-12 | dirkx | Nieuwe druklagers hydrauliek |

| 2021-1 | dirkx | Leibaanolie ververst |

| 2021-1-20 | dirkx | Koelmiddel ververst. |

| 2021-1-5 | dirkx | 2x nieuwe diamand ritsers |

| 2021-2-1 | dirkx | Nieuwe pomp, nieuwe slangen, nieuwe schakelaars |