ER 25/32/40 Collets and holders

This equipment is safety category 5: Equipment that is relatively fragile or expensive

- In person instructions is not mandatory.

- Reading the wiki, and following the instructions, is mandatory.

This equipment is Noise Category 3: Can be used at all hours. No limits.

Set of METRIC collets -- for the ER25, ER32 and ER40 holder of theAbene VHF3 Metaalfrees machine, Metal lathe, Wood Lathe and various other MT2 taper tools.

Inhoud

[verbergen]ER 25

METRIC Sizes 1mm - 15mm -- and each will take 0.5mm for the small collets and from 6mm - 1mm smaller. So actual range is 0.5-1, 1.5-2, ... until 6 to 15mm. Do not use them outside this range. They will break (check the box with the boring bar for examples).

| Label | Range that fits |

|---|---|

| 1 | 0.5 - 1 mm |

| 2 | 1.5 - 2 mm |

| 3 | 2.5 - 3 mm |

| 4 | 3.5 - 4 mm |

| 5 | 4.5 - 5 mm |

| 6 | 5- 6 mm |

| 7 | 6- 7 mm |

| 8 | 7- 8 mm |

| 9 | 8- 9 mm |

| 10 | 9- 10 mm |

| 11 | 10- 11 mm |

| 12 | 11- 12 mm |

| 13 | 12- 13 mm |

| 14 | 13- 14 mm |

| 15 | 14- 15 mm |

| 16 | 15- 16 mm |

ER 32

METRIC Sizes 10, 12, 13, 16, 18 and 20 mm. Each will take up to 1 mm smaller. So the Size 10 will accept 9-10.

The range accepted is inscribed on the top of the collet. Do not use them outside this range. They will break (check the box with the boring bar for examples).

ER 40

METRIC Sizes 23 and 26. Will fit 22-23 mm and 25-26mm. Do not exceed this range. They will break.

Use

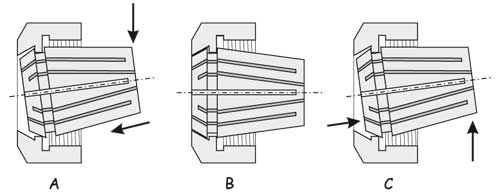

Make sure you `angle-click' the collet into the nut (do not force it straight). Have someone show you if you've not done it before -- as it is easy to get them out of shape this way -- causing vibration.

(from https://www.arceurotrade.co.uk/Catalogue/Collets/ER-Collets/ER40-Collets):

Inspecting the inside of our ER collet nuts reveals an internal flange that has been machined eccentric to the main axis of the nut. This is not a machining error but is designed that way to lock onto the groove of the collet and aid its release from the chuck body.

For this feature to work properly, the collet must be mounted in the nut first before fitting the assembly into the chuck body. To mount the collet in the nut, insert it on an angle, turn slightly and push it into the nut until it clicks into place on the eccentric flange. The cutter may now be fitted and the assembly tightened hard into the chuck body.

To remove the cutter, slacken and undo the nut until resistance is felt. Then, using a collet wrench, further undo the nut until the collet is released from the chuck body. Removal of the collet from the nut is the reverse of the mounting procedure.

Holders - machines

There are MT2 and ISO40 tapers for the Abene VHF3 Metaalfrees machine, Metaaldraaibank, Houtdraaibank and so on.

Holders - vice

We also have two ER25 collet holders; one square, one hex.

To hold something round in a vice; and be able to rotate it at tight/accurate angles.

For example to turn the end of something round into a hex or square that you can rotate with a spanner. Or get a flat side on something round.

Holders - flange

To mount on various machines - to hold round things.

Make sure that the bolt (bout) you use is _shorter_ than the hight; because you do not want to break out the T-Slot by having it hit the bottom of the T groove and then `pushing' up the metal (check the square plate to see the tear-out damage when that happens).

Todo

Would be nice to make / find a box for them.

History & Ownership

Bought June 2019 (ER25) and September 2019 (ER32, ER40). Owned by the Stichting Makerspace Leiden.

One spare nut bought July 2019 to replace borked one. Mail the mailing list if you use up the last spare one.

Rules

This equipment is Noise Category 3: Can be used at all hours. No limits.

Box

Template for a box.