Lathe Tooling

Inhoud

[verbergen]General

This equipment is safety category 3:

- Mandatory, in person, instructions.

- Make sure you read the Wiki before asking.

This equipment is Noise Category 2:

- Can be used at all hours, but in moderation.

- Be considerate; if you feel you need to wear ear protection, then only use the tool between 07:00 and 19:00.

We have various items of lathe tooling for the Metalworking lathe.

This page details what we have.

Work Holding

We have two chucks for the metal working lathe. A three jaw chuck, and a four jaw chuck. The three jaw is normally installed on the lathe. Unless you want to be dialing the work in, this is the chuck you want to use. The four jaw chuck lives under the lathe on a little stand. Lathe Chucks are HEAVY. They are also precision items, try to avoid dropping them. When replacing the lathe chuck, place a block of wood on the ways to protect them.

You need a 14mm spanner to undo the bolts that hold the chuck in place.

In addition to the chucks, there is a face plate. This lives in a drawer on the opposite side of the metal working area below the drill bits.

The lathe spindle bore has a Morse Taper 4 taper ground into it. Maximium diameter that fits through the spindle bore is 26mm.

Supports

There is a steady rest, and a follow rest for the lathe. These currently live in the lathe accessories drawer on the opposite side of the metal working area.

Tailstock tooling

For the Tailstock we have various tools that have a Morse Taper 2 shank. Details of which can be found on the dedicated MT2 page.

Drilling and threading

In the bottom drawer beneath the lathe there is a grey metal box containing taps and associated drills for use on the lathe. These are only to be used with the lathe or mill, and are not for general machining, or hand use.

In the middle drawer there is a 22mm drill with an MT2 taper for use in the tailstock. This drawer also has bulk packs of cobalt drill bits for use in the lathe. These bits appear to be sized for standard metric tapping sizes.

Centre drills can also be found in this drawer, both loose in a plastic bin, and in an HBM branded wooden box.

In addition to cutting threads with the taps and dies, it is possible to cut threads using Single point threading. To do this, a gear combination needs to be selected on via the gear levers on the headstock, as well as making sure the right change gears are selected in the banjo.

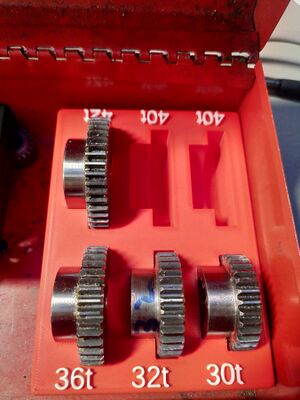

There spare gears not used for the current combination are stored in the red tool box under the lathe to the right, next to the four jaw chuck. There are no markings on the change gears for how many teeth they have, however the 3d printed holder they are stored in is designed so that a gear of a given size only fits in one slot (except for the 40t gears of which there are two of them).

Cutting tools

The most commonly used tools for the lathe are usually kept on a carasel to the right of the lathe behind the tail stock. At the time of writing, the four tools here consist of a triangular carbide insert tool, a diamond carbide insert tool, a 2mm wide carbide insert parting/grooving tool, and two knurling tools (single wheel and double wheel) (Can someone confirm this correct?).

Additional carbide insert tools can be found in the top drawer below the lathe. There are a lot of different tools in this drawer, they include threading tools, boring bars, as well as general cutting tools.

In the second drawer down there is a set of HBM HSS lathe tools in a wooden box.

Replacement inserts for the carbide insert tooling can be found in the bottom drawer. There is a wide selection of inserts here. Please make sure you choose the correct one. If we are running low of a particular type, either order more from aliexpress, or email the list. There's 4 tins of enamal paint here for colour coding things. (can someone who knows about these document this?)

Misc

In addition to all the tools listed above, there are various other items in the lathe accessories drawer on the other side of the metal working area. What these all are is not yet documented.

This includes one lathe dog (drive dog) for turning between centres. More info on turning between centres can be found on the Turning_Between_Centres page.